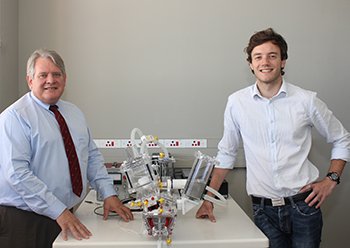

Prof Francis Smit, Head of the Department of

Cardiothoracic Surgery at the UFS, and Manager of the

Robert WM Frater Cardiovascular Research Centre, with

Kyle Davis, Mechanical Engineer at the centre.

Photo: Rulanzen Martin

Three heart-valve studies which have been developed at the Robert WM Frater Cardiovascular Research Centre at the School of Medicine at the University of the Free State (UFS) were recently presented in Monte Carlo at the conference of the prestigious global Heart Valve Society (HVS).

These studies are all headed by Prof Francis Smit, Head of the Department of Cardiothoracic Surgery at the UFS, and Manager of the Robert WM Frater Cardiovascular Research Centre.

Prof Smit says the HVS is a combination of the former heart-valve societies of Europe and the US. “Studies on heart-valve disease, heart-valve-related products and operations, as well as the design and development of new valves were presented. There are both clinical and development divisions.

He says the study in which the hemodynamics of their redesigned mechanical poppet valve was compared to a commercial bi-leaflet mechanical heart valve, was named as the best poster presentation in the experimental valve development and numerical flow dynamics division. The study, which was presented by Kyle Davis, mechanical engineer at the centre, competed against some of the best heart-valve research units in the world.

The redesigned valve, based on the 1960s Cape Town poppet valve, has the potential to provide a low-cost solution for mechanical heart-valve replacement. It is possible to produce the titanium ring with 3-D printers and is, together with the silicon poppet valve, extremely inexpensive compared to current mechanical valve-manufacturing processes.

The advantages of this valve over current mechanical valves is that, due to the effective and laminar flow characteristics, as well as the simple locking mechanisms, there is a reduced chance of valve thrombosis, and the need for anti-clotting drugs is therefore limited.

It was also confirmed that the new valve more than meets the published FDA (Federal Drug Agency) requirements, which determine the minimum standards of valves for human use in the US.

The redesigned valve also has a very low platelet activation impact, which is responsible for platelet thrombosis and leads to valve thrombosis or strokes. This valve is another heart-valve project by the centre, which is also in the process of evaluating a tri-leaflet polyurethane valve developed by them.