A student from the University of the Free State (UFS) has made a ground-breaking discovery in the field of microbiology by uncovering a series of new compounds that may in future be used to lubricate man-made nanorobots.

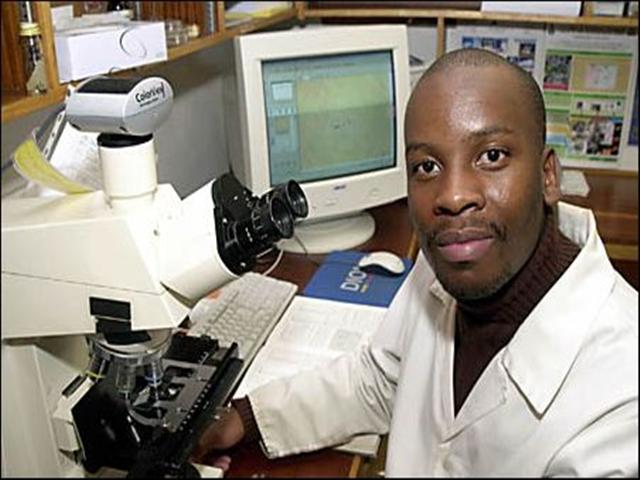

Mr Olihile Sebolai, a full-time student at the UFS’s Department of Microbial- Biochemical and Food Biotechnology, made this discovery while working on his M Sc-study on yeast.

With this discovery Mr Sebolai will also be awarded six prestigious prizes during this week’s autumn graduation ceremony at the UFS. This university has recognised this exceptional achievement as a build-up to the celebration of national Science and Technology week next month.

Mr Sebolai’s dissertation on the yeast genus Saccharomycopsis Schionning has been published in an accredited international journal of repute.

“Words cannot describe how excited I am. I never expected to receive such recognition for my studies. I am humbled by all of this,” said Mr Sebolai.

The Lipid Biotechnology Group at the UFS recently discovered that some yeasts produce their own water-propelled capsules in which they are transported. These capsules have different shapes and resemble among others miniature flying saucers, hats with razor sharp brims etc. “In order to function properly, parts of the capsules are oiled with prehistoric lubricants – lubricants that are produced by yeasts and that probably existed for many millions of years as yeasts developed,” said Mr Sebolai.

According to Mr Sebolai these capsules are so small that approximately 300 can be fitted into the full-stop at the end of a sentence and are therefore invisible to the naked eye.

“With my studies I discovered many new compounds that resemble these prehistoric lubricants. These lubricants may in future be used to lubricate man-made nanorobots and are similar in size compared to yeast capsules,” said Mr Sebolai. The nanorobots are used to perform tasks in places that are invisible to the naked eye and could one day be used, among others, to clean up human arteries.

Mr Sebolai has been interested in the subject of Micro technology since he was at RT Mokgopa High School in Thaba ‘Nchu. “I was specifically interested in the many possible applications the subject has – in the industry, as well as in medicine,” said Mr Sebolai.

His next goal is to successfully complete his Ph D-degree.

The prizes that will be awarded to Mr Sebolai this week include:

Best Magister student at the UFS (Senate medal and prize);

Best Magister student in the Faculty of Natural and Agricultural Science and Dean’s medal at the same faculty;

The Andries Brink – Sasol-prize for the best M Sc dissertation in Microbiology;

The JP van der Walt prize for best M Sc dissertation in yeast science;

The Chris Small prize for an outstanding Master’s dissertation; and

Honorary colours awarded by the UFS Student Representative Council

Media release

Issued by: Lacea Loader

Media Representative

Tel: (051) 401-2584

Cell: 083 645 2454

E-mail: loaderl.stg@mail.uovs.ac.za

20 April 2005